Automated Assembly Systems

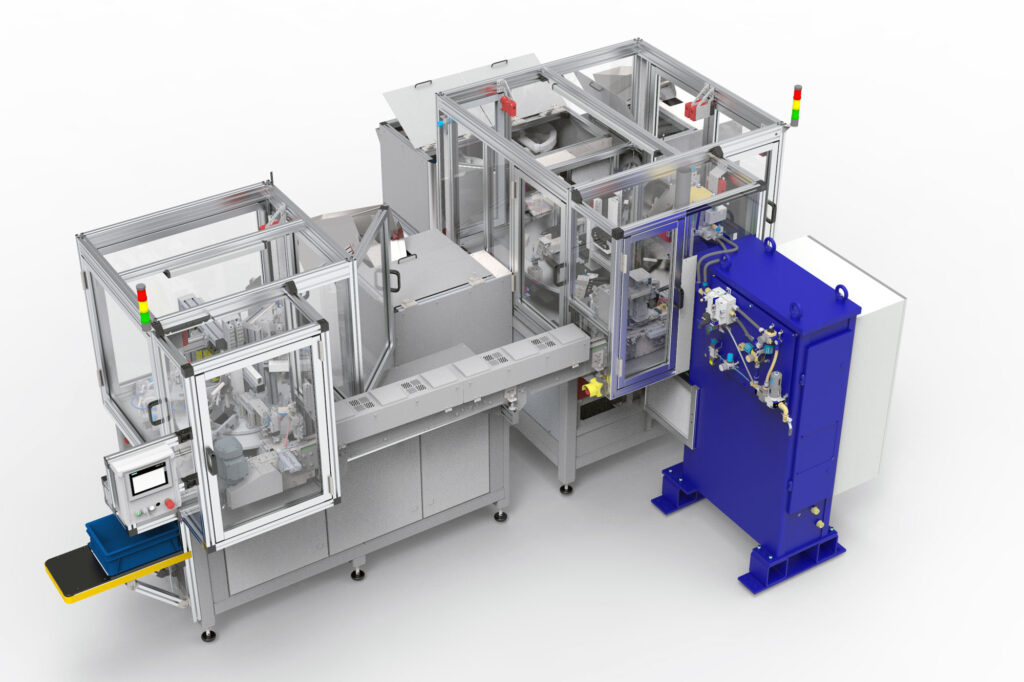

We make automated assembly systems for mechatronics and electronics production.

System platforms

- Robotic Assembly Cells

- Rotary Indexing Assembly Machines

- Pick & Place Assembly Systems

Industries

- Automotive, Electronics, Telecom, Medical and other

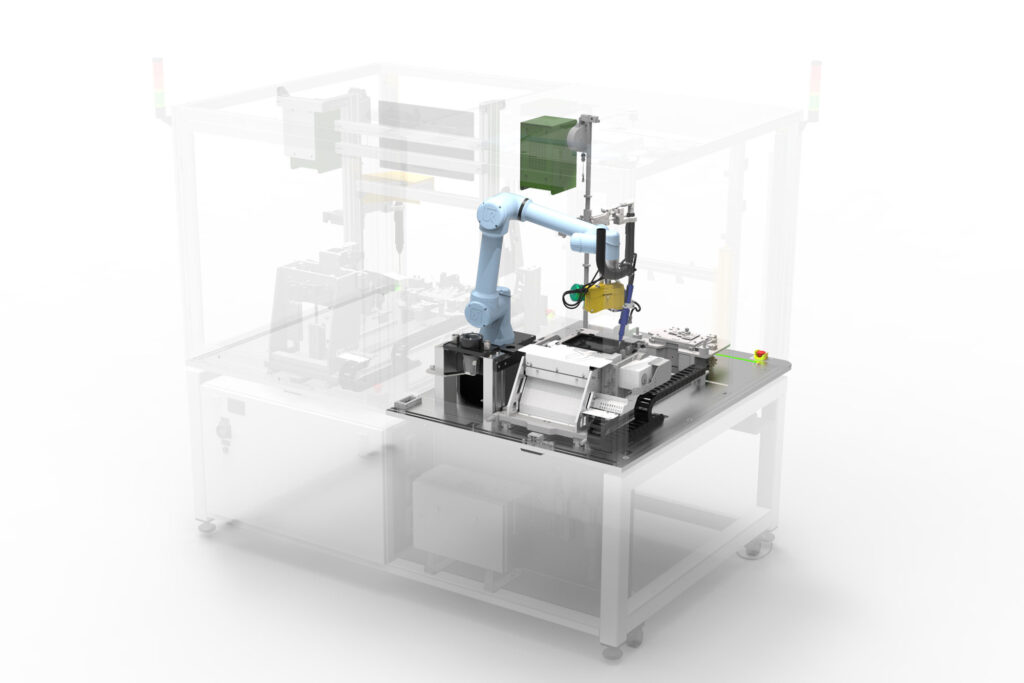

Robotic Assembly Cells

Fully automated assembly systems based on 4-6 axis robots.

- collaborative & industrial robots

- 6-axis robots

- SCARA robots

- delta robots

We are an open integrator with experience in various fields & brands.

Rotary Indexing Assembly Machines

Fully automated assembly systems based on rotary indexing tables.

- pneumatic rotary indexing tables

- electrical rotary indexing tables

- servo motor rotary index tables

Our rotary indexing machines are on average with 6-12 assembly positions.

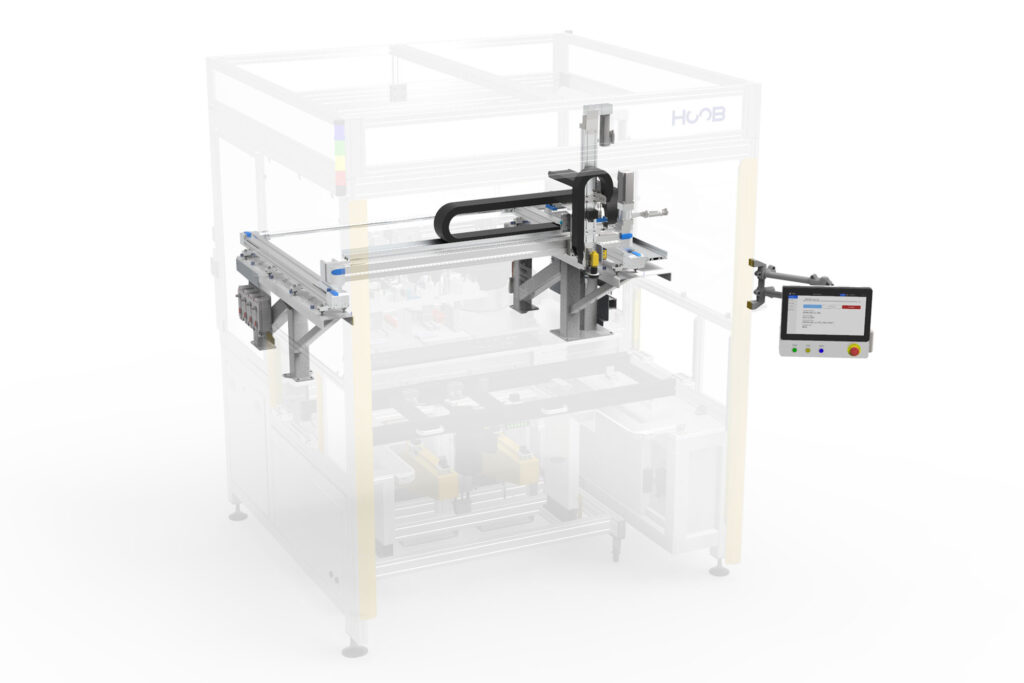

Pick & Place Assembly Systems

Fully automated assembly systems based on Gantry robot systems.

- 3-axis Gantry robots (Cartesian crobots),

- linear servo motor axis with CNC motions tools,

- large workpiece area,

- high accuracy,

- load measurig systems.

Main functions

- Automated component feeding – feeders are designed and integrated to suit each individual component.

- Automated assembly – robotized assembly processes by using linear or multi axis actuator systems.

- Integrated quality control – each assembly step is controlled and verified with quality measurements.

- Integrated machine vision – camera and sensor modules ensure the most accurate and reliable assembly procedures.

- Ergonomic user interface – our Human-Machine-Interface (HMI) is easy to operate.

Main benefits

- High productivity – automated assembly systems enable short cycle times.

- Stable assembly process – precise positioning and precise robotic drives boost quality of end products.

- Low labor cost – automated assembly systems reduce the need for operators.

- Low maintenance needs – less maintenance due to proven & tested technical solutions.

- Saves factory floor space – complete assembly process in a compact format.

- Easy to relocate – cells can be easily transported to a new location, and production can restart quickly.

Pick & Place Assembly Cell for Board-to-Board Adapters (EBC Bullets)

This is an automated assembly system for Board-to-Board connector adapters (or Bullets). For example the assembly robot is suitable for Rosenberger’s EBC (Efficient Board Connector) series. The system is meant to work autonomously – it can feed components, load and …

Thermal Paste Dispensing Robot for Electronics Industry

A robotic thermal paste dispensing solution for electronics industry. The system is meant for applying and checking thermal paste withing final assembly process.

Seal Dispensing & Assembly System for Display Unit

Automotive electronics have high visual requirements. Our customer needed an assembly and seal dispensing system for display unit.

References

Stories of our customers.

HOOB is a reliable partner for every production company. With us, you can be sure that, until the end of the final project and beyond, we will think with the customer and be ready to further develop automation and robotics solutions.

Why choose Hoob as a partner?

World class reference

Our customers are world`s top players in industrial sector.

Turnkey systems

We deliver complete and tested systems to allow smooth start up at your factory.

We help to grow your business

Our goal is to find a suitable automation level that returns your investment at excpected time.

Professional team

Strong feedback from customers about professional engineering and project management team.

Warranty & technical support

All our systems come with a warranty and technical support for maintenance, updates and spare parts.