SUBCONTRACTING SERVICES

Engineering Service

We offer engineering services for industrial fields. Our core know-how is engineering and machine building for industrial automation and production processes. Our engineering department has the ability to design mechanics, automation, electrical systems and software.

Benefits of outsourcing

- Optimise your engineerings cost by reducing headcount

- Free up time to focus on your company mission

- Increased flexibility to tackle workload fluctuations

- Increased talent pool by enlarged contact network

Automation Concepts

- Conceptual design solutions for machines and production automation systems

- Prototypes & proof of concepts

- Technical descrpitions of functions

- Equipment specification documents generation

- Cost and lead time calculations

- Return-of-Investment calculations (ROI)

- Simulation and visualisation

Mechanical Engineering

- Mechanical engineering and system design

- 3D modeling (Solidworks software)

- Creation of manufacturing and assembly drawings

- Design For Manufacturing (DFM)

- Bill Of Materials

- Risk assesments according to ISO 12001

- Process Failure Mode Effects Analysis (PFMEA)

- Creating machine documentation and manuals

Electrical Engineering

- Design of Electrical Systems for Industial Automation (Eplan software)

- Control Panel layouts

- Electrical schematics

- Communication and interface solutions

- Risk assesments according to ISO 12001

- Process Failure Mode Effects Analysis (PFMEA)

- Bill of Materials generation

Software Development

- Software development for industrial applications

- (Siemens, B&R, Mitsubishi, ABB, Festo, etc)

- Software for controlling Servo motors and axis

- Software development for industrial controllers (PLC)

- Implementation of communication protocols

- (PROFINET, Profibus, Powerlink, Modbus, OPC UA, etc)

- Human-Machine-Interface (HMI) design

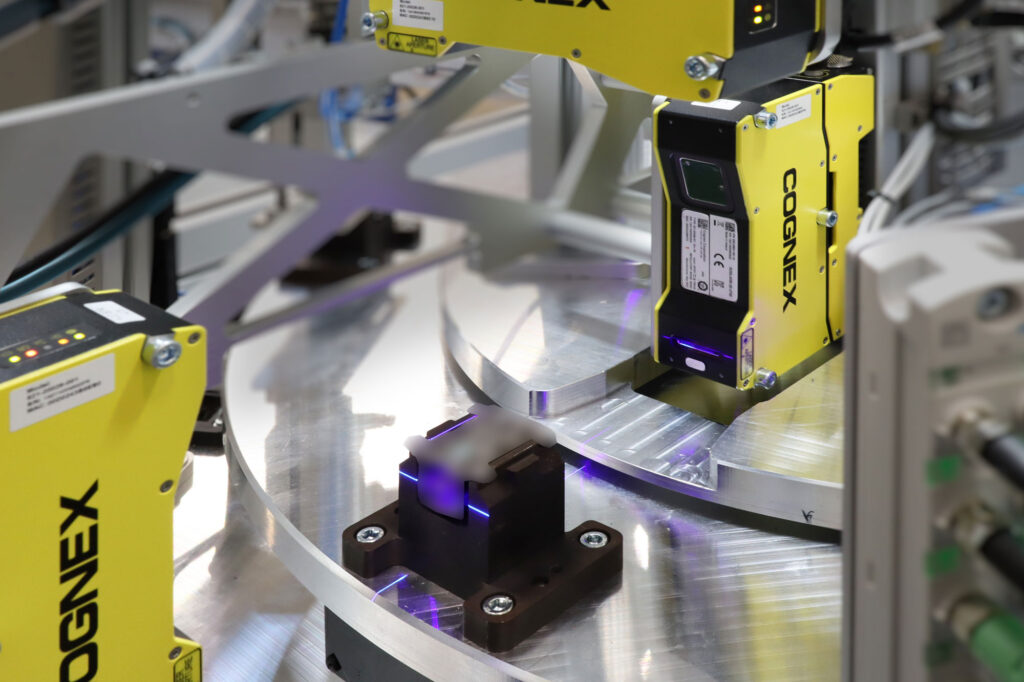

Machine Vision Development

- Colour recognition

- Optical character recognition and verification (OCR, OCV)

- Detection of 1D and 2D barcodes, matrix codes

- Inspection of assembly components

- Presence and location of a component

- Checking the geometry of the product

- Product quality control, dimensional measurements

- Deep learning, Development of Vision Guided Robotics

Production line for EV chargers

State-of-the-art Assembly & Test Line to a leading player in the electric vehicle (EV) industry. This production line uses a large product carrier through the assembly and test phases. Product is assembled on a pallet through several phases and transported …

Pick & Place Assembly Cell for Board-to-Board Adapters (EBC Bullets)

This is an automated assembly system for Board-to-Board connector adapters (or Bullets). For example the assembly robot is suitable for Rosenberger’s EBC (Efficient Board Connector) series. The system is meant to work autonomously – it can feed components, load and …

Thermal Paste Dispensing Robot for Electronics Industry

A robotic thermal paste dispensing solution for electronics industry. The system is meant for applying and checking thermal paste withing final assembly process.

References

Stories of our customers.

HOOB is a reliable partner for every production company. With us, you can be sure that, until the end of the final project and beyond, we will think with the customer and be ready to further develop automation and robotics solutions.