Test Systems

We make test stations for factories and industrial sector.

-

Systems

- Electrical Test Stations

- Functional Test Stations

- Software Loading Fixtures

- Leakage Testers

- RF (Radio Frequency) Test Fixtures

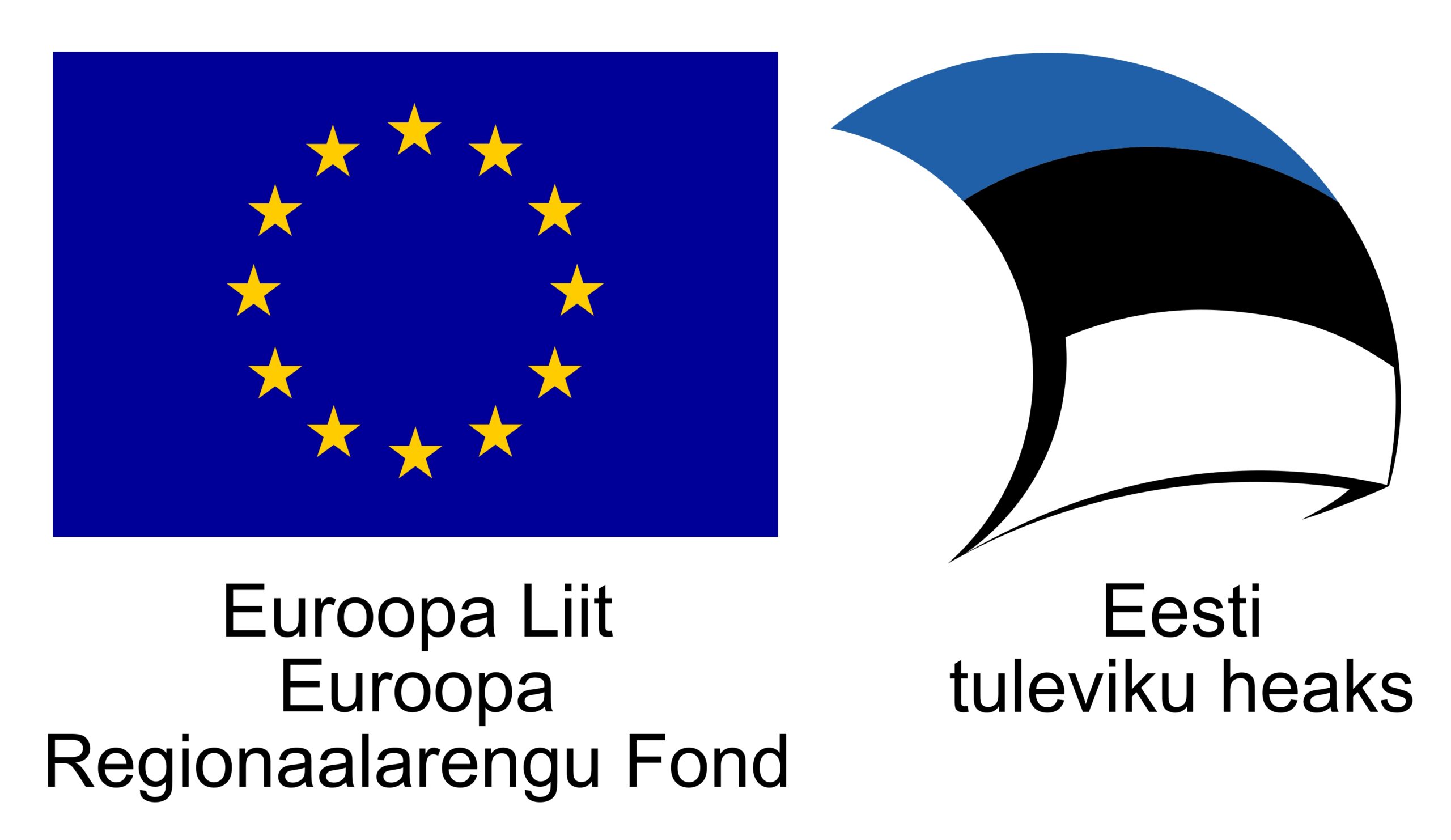

Electrical & Functional Testers

- Electrical tests

- Current & load measurements, safety tests

- Circuit board testing with test needles

- End Of Line (EOL) testers

- Functional tests

- Force and stroke measurements (push buttons, rotary knobs)

- LED control (ignition, off)

- Dimensional checks, product life cycle tests

Software Loading Fixtures

- Software loading

- Automated software loading

- PCB flashing and programming

- PCB test needle assemblies

- Circuit board testing with test needles

- Test sockets and test needle assemblies

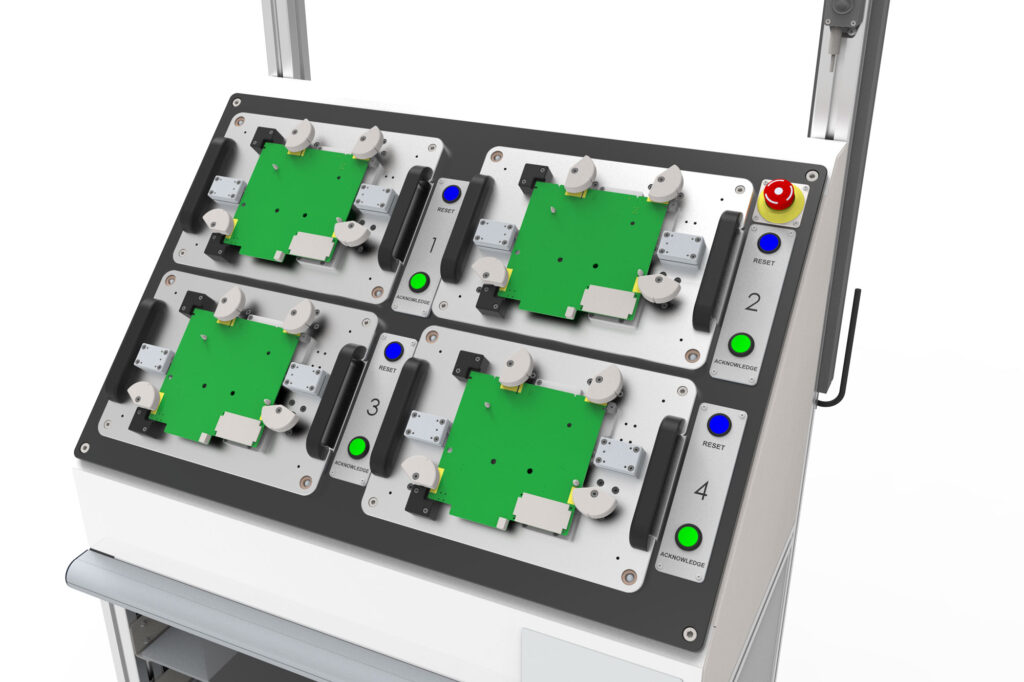

Leakage Testers

Leakage testing

- Testing the IP requirements of the products that have to be air or liquid proof

- Testing with overpressure or vacuum

Flow testing

- Determing the air flow through product (membrane, etc)

RF (Radio Frequency) Test Fixtures

- Shielded, non-reflective measurement of high frequency signals

- Outstanding shielding attenuation frequency domain up to 6 GHz

- RF-compatible shielding for RF PCBs

- Quick-exchange system

CUSTOMER REFERENCE

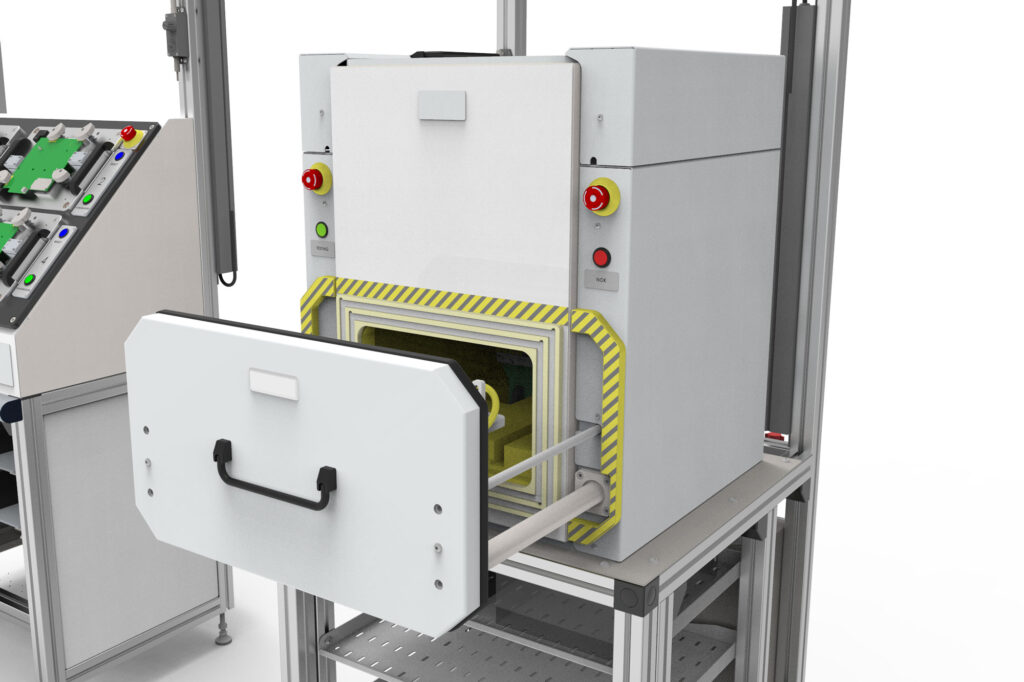

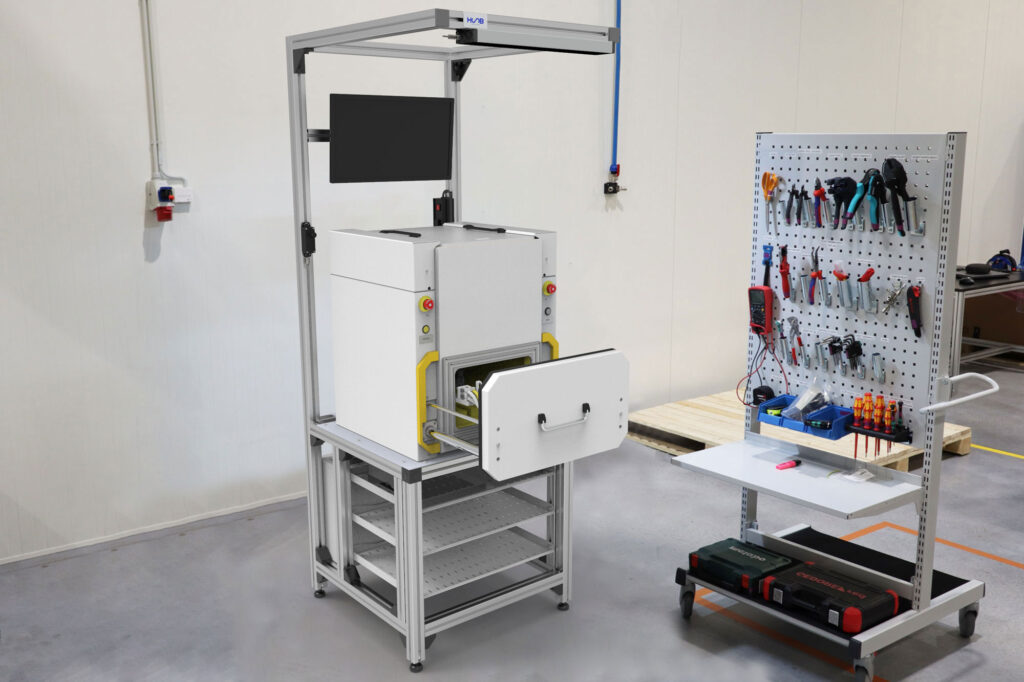

Test Station for Electronics Control Unit

We delivered Test Station for ECU product that saves factory floor space and allows compact assembly line layout.

Read more

CUSTOMER REFERENCE

Radio Test Station for Telematics Product

Customer needed a Radio Test Station that comfortable to use on the assembly line for every single product.

Read more

CUSTOMER REFERENCE

Leakage Test Station for Electronics Control Unit

We created a test system for testing Electronics Control Unit`s IP requirements.

Read more

Production line for EV chargers

State-of-the-art Assembly & Test Line to a leading player in the electric vehicle (EV) industry. This production line uses a large product carrier through the assembly and test phases. Product is assembled on a pallet through several phases and transported …

Pick & Place Assembly Cell for Board-to-Board Adapters (EBC Bullets)

This is an automated assembly system for Board-to-Board connector adapters (or Bullets). For example the assembly robot is suitable for Rosenberger’s EBC (Efficient Board Connector) series. The system is meant to work autonomously – it can feed components, load and …

Thermal Paste Dispensing Robot for Electronics Industry

A robotic thermal paste dispensing solution for electronics industry. The system is meant for applying and checking thermal paste withing final assembly process.

References

Stories of our customers.

HOOB is a reliable partner for every production company. With us, you can be sure that, until the end of the final project and beyond, we will think with the customer and be ready to further develop automation and robotics solutions.